Metal Rust:

|

| Before |

|

| Bump |

|

| Spec |

|

| After |

Concrete Mossy:

|

| Before |

|

| Bump |

|

| Spec |

|

| After |

Concrete Rough:

|

| Before |

|

| Spec |

|

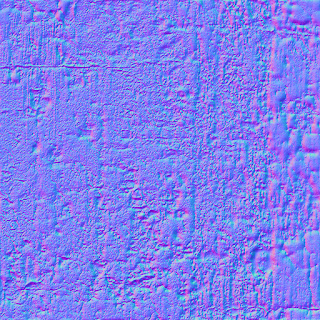

| Bump |

|

| After |

Concrete:

What

is the process of making the material?

Concrete is primarily composed of

aggregate (limestone or granite), cement and water. The materials are mixed

together and then poured into a set caste. Once poured it must be placed in a

controlled environment in order for it to dry at a set pace in order to reach

its maximum strength.

How

long will the material last: The material can last for a long time but

effects such as sea water and bacteria can reduce its life span.

What

makes the material corrode? The material corrodes through

actions such as the corrosion of the reinforcement bars within it, sea water,

bacteria and many others.

What

are the material's structural pros and cons? The materials pros are

that it can last a long time and is very easy to make. It is also very strong

in compressive strength. Cons are that

if not set correctly it can crack and its strength is dramatically reduced. It

is also weak in tensile strength.

What

is the material typically used for: The material is typically used for the

supports and columns of buildings such as high rise and multistorey residential.

What

are the material's environmental impacts? These could include the excess

amounts of C02 that is created in trying to mine all the materials

as well as make them into suitable products for cement mixing. Concrete is also

used to create hard surfaces that contribute to surface runoff, which can cause

soil erosion, water pollution and flooding. It is also a thermal heat retainer

which causes increased temperatures in areas full of concrete such as cities.

Glass:

What

is the process of making the material? Glass is a non-crystalline

solid material. The most common is soda-lime glass, composed of about 75% silica

plus NA2O, CaO, and several other additives.

How

long will the material last: The material should last a long time since

not many things affect it. It is very brittle, so as a result if it is placed

in an unstable environment it could crack and/or break.

What

makes the material corrode? As time progresses moisture and bacteria have

an effect on glass. They start to attack its structure which as a result tends

to lead to a murky colour replacing the clear view it provides when new.

As time progresses, many things can add

to the decay of glass. As it is a very brittle material it can crack. Factors

such as high gale winds, rockslides, animals and trees can all cause cracks in

the glass or destroy it completely.

What

are the material's structural pros and cons? The

materials pros include the ability to provide shelter whilst providing a view.

A con is that it is very brittle and after a long time its transparent view can

turn murky.

What

is the material typically used for: The material is mainly used for windows in

order to provide a transparent section in which a view can be seen whilst

providing protection from the outside elements.

What

are the material's environmental impacts? The immense amounts of heat used

in order to create glass produces a lot of C02.

Steel:

What

is the process of making the material? Steel is an alloy made from combining

iron and other elements, the most common being carbon. Iron must be smelted

under intense heat in order to remove the oxygen that is attached to it in its

earth found form, iron ore. The smelting releases the oxygen attaching carbon

to the iron allowing a material that can be mixed with other materials to

produce steel.

How

long will the material last: Steel can last for some time if

maintained properly. Without maintenance steel corrodes from the oxygen in the

air, causing rust.

What

makes the material corrode? Oxygen makes the air corrode. As a

result any environment can cause steel to rust, except for highly dry areas

such as those found in the Arizona desert which contains minute traces of water

meaning rust can’t take effect as easily.

What

are the material's structural pros and cons? Steel can

be made for specific reasons to tackle specific problems and as a result is a

very good structural material. Varying the amount of alloying elements, and the

form of their presence in the steel, controls qualities such as hardness,

ductility and the tensile strength of the resulting steel. One of the only

drawbacks in steel is its increase in weight the larger to pieces become and

the affect that natural elements such as water and oxygen can have on it over

time.

What

is the material typically used for: The material is typically used for columns

and beams since they can be built specifically for tensile or compressive uses.

It is mainly used in high rise buildings, bridges and cantilevered edges.

What

are the material's environmental impacts? To produce steel iron

must be mined and then smelted in order to extract the ore. As a result the

environmental impacts could include CO2 emissions as well as

environmental degradation due to open cut mines.

No comments:

Post a Comment